The plans call for silver soldering each end before machining, others have used epoxy, and others use a Loc-Tite product for cylindrical parts.GeorgeGaskill wrote:Silver soldering the liners to the tubes seems like gross overkill, not to say gross overheating. Is that really necessary?

1/2 scale Gatling

Re: 1/2 scale Gatling

Re: 1/2 scale Gatling

Looks like you are doing a fine job, the guns are a lot of work. Many small pieces. I used barrel liners and dom tubing, and used brownells acraglas rather than soldering the liners in.

Where in AZ are you?

Where in AZ are you?

Re: 1/2 scale Gatling

Wow, nice job! I'm in west Phoenix.Rolland wrote:Looks like you are doing a fine job, the guns are a lot of work. Many small pieces. I used barrel liners and dom tubing, and used brownells acraglas rather than soldering the liners in.

Where in AZ are you?

Re: 1/2 scale Gatling

do you have all the corrections on the plans? There are a number of them.

Re: 1/2 scale Gatling

The ones that are published I am aware of, but I've run across other mistakes/omissions on my own. I just don't understand why Paul never updates his plans, or at the very least prints out a sheet detailing the mistakes with every set of plans he sells?Rolland wrote:do you have all the corrections on the plans? There are a number of them.

Re: 1/2 scale Gatling

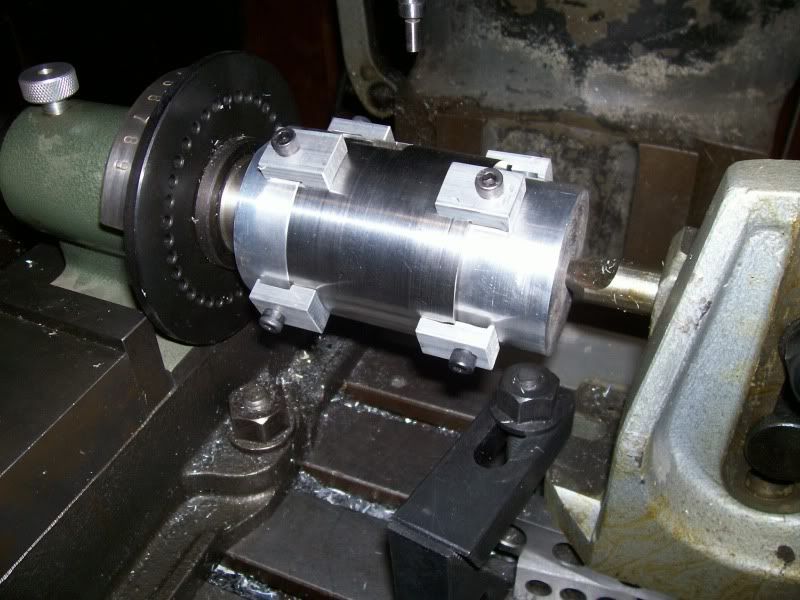

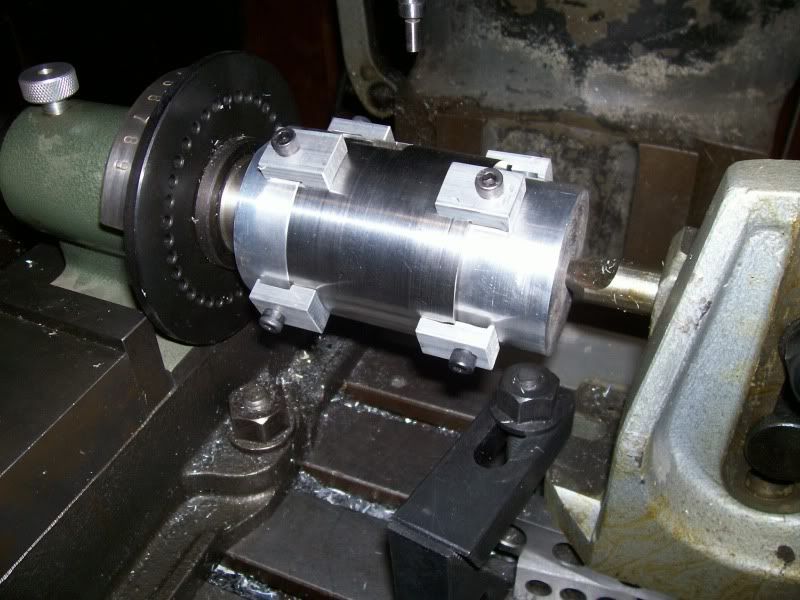

This is the fixture I made to cut the slot in the box cam with the cam blank mounted. A member of the Gatling gun forum plotted the tool path by degrees and posted them so what I plan to do is plunge cut, withdraw the endmill, rotate the indexer one degree, repositon in the X axis, plunge cut, etc. until I have two halves.

I'll have to do quite a bit of hand blending, but this is the only way I could think of to do it with the equipment at my disposal.

I share my 220v line with my clothes dryer or I would have started cutting the slot already.

I'll have to do quite a bit of hand blending, but this is the only way I could think of to do it with the equipment at my disposal.

I share my 220v line with my clothes dryer or I would have started cutting the slot already.

Re: 1/2 scale Gatling

Of all the pieces in the gun this one is the most demanding to make and line up propertly. I lost hair, sleep, skin, and my youthful appearance working on this one. I had the same or close to same set up.

Re: 1/2 scale Gatling

Rolland wrote:Of all the pieces in the gun this one is the most demanding to make and line up propertly. I lost hair, sleep, skin, and my youthful appearance working on this one. I had the same or close to same set up.

I plan to drill & tap the four offset holes that line up with the side rails and breech casing, mount the cam blank in the breech casing, and then use the same fixture to drill & tap the other eight mounting holes, take it all apart, put the cam back on the fixture, and cut the slot.

There's a .500 pin in the fixture indexed to 15 degrees to clock the bolt extractor slot on, so it will be easy to take it off and on without losing TDC.

Re: 1/2 scale Gatling

I could use some help from one of you guys that has CAD software. I need to plot the toolpath in one degree increments to cut the slot in the boxcam for this project. The slot starts at TDC and .925 from one end of the cam. The slot continues around the cam at the .925 position until 36 degrees, then I need to cut it diagonally to 2.100 inches from the end until it reaches the 162 degree mark in rotation. From there it remains at 2.100 until 210 degrees, then cuts back diagonally to the .925 position at 342 degrees. I hope this makes sense.

Can anyone help me out?

Edit: Nevermind, I got it. Thanks

Can anyone help me out?

Edit: Nevermind, I got it. Thanks

Re: 1/2 scale Gatling

Got the cam done today. I drilled the mounting holes first, then cut the slot. Just need to do a little blending and it's good to go.

Re: 1/2 scale Gatling

That sucker really looks good! You been doing this long? (machining)my65pan wrote:Got the cam done today. I drilled the mounting holes first, then cut the slot. Just need to do a little blending and it's good to go.

Harold

Wise people talk because they have something to say. Fools talk because they have to say something.

Re: 1/2 scale Gatling

Thanks, I've been machining for going on 25 years now.Harold_V wrote:That sucker really looks good! You been doing this long? (machining)my65pan wrote:Got the cam done today. I drilled the mounting holes first, then cut the slot. Just need to do a little blending and it's good to go.

Harold