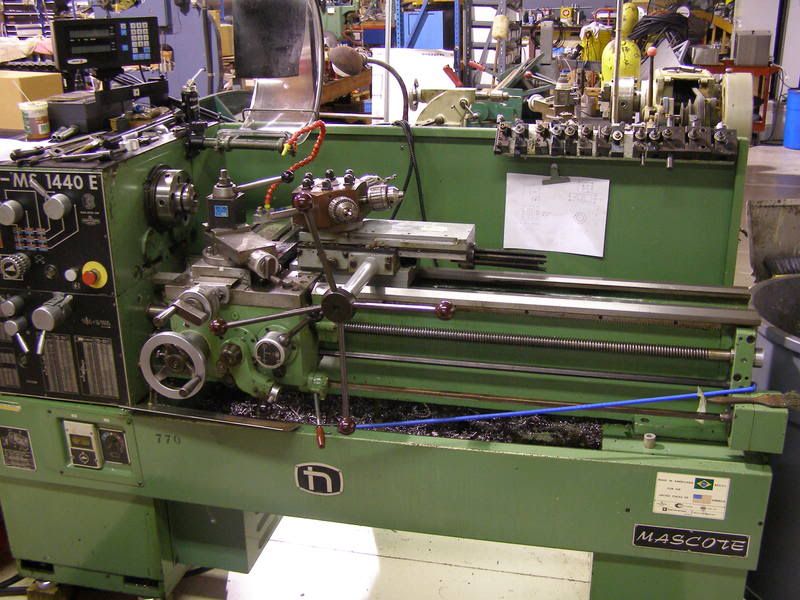

I use the Lexan one listed in the MSC, Enco catalog and like it except for the fact that the lexan cracks from opening and closing it and needs to be replaced occasionally. I'll work on the next one and polish the edges before I install it. I hung a rubber sheet on the front edge of it to stop the little stuff and coolant from flinging out onto the floor. Can't see it too well in the pic with it open, but it's up there.

The "bungee cord mod" is my favorite. The "foreword" "off" "reverse" lever has a nice notch to lock it in "off", but they had no spring to hold it there so I just grabbed a bungee cord as a temporary thing and it worked great! (still "temporary") You havn't lived until you drop a tool holder, chuck key, or something on the lever and it starts in reverse when you're not expecting it. Especially if you were in there with a micrometer and knocked something off with your elbow that hit it and started it or even just bump it with your leg!!

A 10" chuck at 2K with the jaws backed out past the body must be a real eye opener

Glenn