how to determine proper major or minor diameters on oddball

- 737mechanic

- Posts: 373

- Joined: Thu Jun 04, 2009 6:27 pm

- Location: Dallas

how to determine proper major or minor diameters on oddball

There are many times when I am making a part and the thread diameter ends up not being a standard size for instance I have a part with a inner diameter of .823 that I am going to thread with a 28 tpi internal thread. What I need to find is what the matting parts major diameter needs to be so I can do a external thread on it so it fits good. I have always just eye balled this and end up getting it by continuing to thread until it finally fits but I would like to get the major or minor turned to the right size before I start threading to make my machining more productive and proper.

Re: how to determine proper major or minor diameters on oddb

Try this

http://theoreticalmachinist.com/Threads ... erial.aspx

I just ran across it yesterday while looking for something else.

http://theoreticalmachinist.com/Threads ... erial.aspx

I just ran across it yesterday while looking for something else.

Glenn

Operating machines is perfectly safe......until you forget how dangerous it really is!

Operating machines is perfectly safe......until you forget how dangerous it really is!

- warmstrong1955

- Posts: 3568

- Joined: Thu Mar 18, 2010 2:05 pm

- Location: Northern Nevada

Re: how to determine proper major or minor diameters on oddb

Or this:

If you enter your .823" ID as the OD, and the TPI, you get .7843" for the nut hole diameter. Add the difference between .823" and .7843", and then enter that (.8617") in the outside diameter, and there ya go....data for both threads.

Bill

If you enter your .823" ID as the OD, and the TPI, you get .7843" for the nut hole diameter. Add the difference between .823" and .7843", and then enter that (.8617") in the outside diameter, and there ya go....data for both threads.

Bill

Today's solutions are tomorrow's problems.

Re: how to determine proper major or minor diameters on oddb

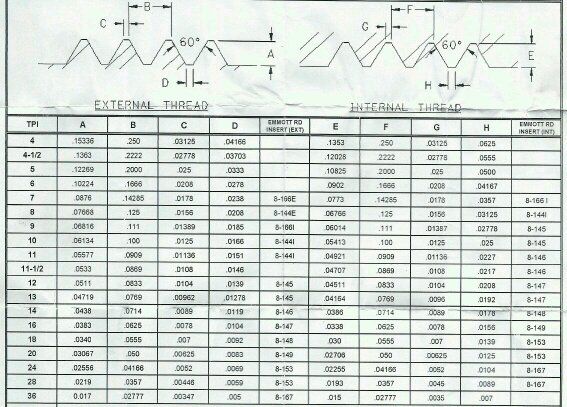

The Atlas-Craftsman manual of lathe operation & machinist's tables has a table showing double depth of thread (difference between major & minor diameter) for threads per inch from 4-96. Also gives the depth of feed for the compound to obtain proper thread depth when set at 29*...Uh-oh, did I just discover another reason to set the compound at 29?  Using double depth of thread will work for any odd diameter..just use your OD for the major, & subtract the double depth to get the minor...the table has values for National Form or V-form tools...

Using double depth of thread will work for any odd diameter..just use your OD for the major, & subtract the double depth to get the minor...the table has values for National Form or V-form tools...

-

mclarenross

- Posts: 15

- Joined: Thu Dec 06, 2012 11:04 pm

Re: how to determine proper major or minor diameters on oddb

I have a chart that I got from a place I use to work that tells me the actual single thread depth for either ID or OD thread forms for threads from 4tpi up to 40tpi or so. Ill post it if y'all want.

Lance Corporal of Marines

-

mclarenross

- Posts: 15

- Joined: Thu Dec 06, 2012 11:04 pm

Re: how to determine proper major or minor diameters on oddb

My home brew recipe is to take the infeed depth of the thread you are going to cut. In this case it is 28 tpi. Finding the infeed depth:

Example, for 28TPI threads:

0.64952/28=0.023 inches (that would be straight in)

Take that .023 and double it for a diameter equals .046.

Now add that to the inside diameter of the pipe; 0.823 + .046= 0.869, minus some for clearance, I use .008 to .010 would give you .0861 to 0.859

For easy ref;

Example, for 28TPI threads:

0.64952/28=0.023 inches (that would be straight in)

Take that .023 and double it for a diameter equals .046.

Now add that to the inside diameter of the pipe; 0.823 + .046= 0.869, minus some for clearance, I use .008 to .010 would give you .0861 to 0.859

For easy ref;